Introduction

In the fast-evolving world of product branding and customization, businesses seek efficient, versatile, and high-quality printing solutions. This article delves into the various printing technologies — screen printing, pad printing, hot stamping, and heat transfer film — that can elevate your product’s market presence. Featuring YXF Labels, a leader in customizable label solutions, we explore how these technologies can be integrated into a holistic branding strategy.

Screen Printing

Overview: Screen printing involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface. Each color is applied using a different stencil, one at a time, to achieve the final look.

Applications: Ideal for designs that demand vibrant colors, screen printing is commonly used on everything from t-shirts and banners to electronics and automotive parts. Its versatility in material and ink compatibility makes it a preferred choice for high-volume orders.

Pad Printing

Overview: Pad printing is a versatile printing technique that transfers a 2D image onto a 3D object. This is achieved using an indirect offset printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate.

Applications: Particularly useful for printing on irregular surfaces such as promotional products, appliances, and medical items. Pad printing is renowned for its precision in small graphics like logos on intricate gadgets.

Hot Stamping

Overview: Hot stamping is a dry printing method in which a heated die and foil are used to apply graphics to a surface. It offers not only metallic finishes but also pigmented foils.

Applications: This technique is widely used in high-end product labeling, including cosmetics, wine bottles, and luxury goods packaging. It provides a distinctive look that enhances aesthetic appeal and perceived value.

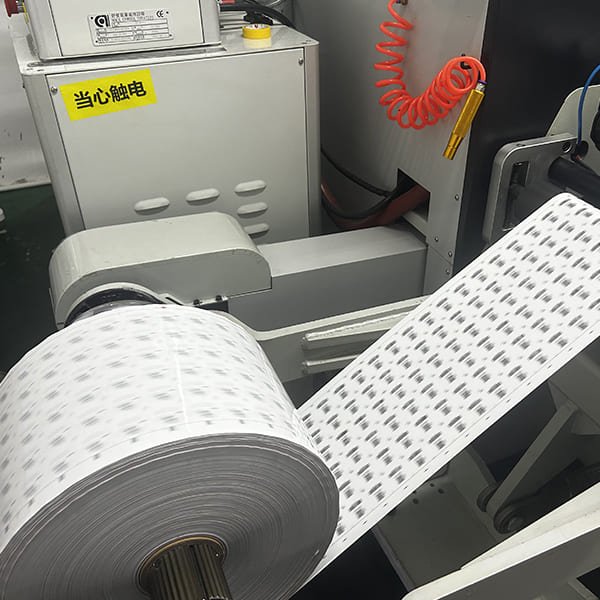

Heat Transfer Film

Overview: Heat transfer involves printing a design onto a special heat transfer paper or film and then thermally transferring it onto the surface of the substrate using heat and pressure.

Applications: Heat transfer film is ideal for detailed and full-color images on apparel, as well as on products like mugs and mouse pads. It offers excellent color fidelity and is capable of handling complex designs with ease.

Integration with YXF Labels

YXF Labels Advantage: At YXF Labels, we provide comprehensive label solutions that integrate these technologies to enhance your product’s branding. Our high-quality, customizable labels ensure that every client’s needs are met with precision, whether they require durability in industrial applications or aesthetic sophistication for consumer goods.

Custom Solutions: YXF Labels specializes in creating custom labels using a variety of materials and technologies to meet specific environmental and durability requirements. From design through execution, our labels are crafted to enhance brand identity and consumer engagement.

Conclusion

An effective overall printing solution requires a blend of technology, expertise, and creativity. By leveraging technologies like screen printing, pad printing, hot stamping, and heat transfer film, businesses can achieve superior product customization and branding. Partnering with YXF Labels ensures access to top-tier printing solutions tailored to meet diverse industry needs, reinforcing brand presence in a competitive market.